|

| Inline refractometers are used for jam and jelly production to ensure consistency and quality. |

This post is intended to give a basic understanding of the use of inline refractometers in commercial food and beverage production.

According to Wikipedia, "Refraction is the change in direction of wave propagation due to a change in its transmission medium."

To understand more clearly, consider this. If you place a pencil in a jar of standing in water and look through the jar, it appears to be broken at the water line. When you add sugar to the water, the pencil appears to bend even more. The reason for this is because light travels slower in water than through air. When you dissolve materials (sugar) in the solution, the light will travel even slower. Understanding this basic concept allows you to understand how you can measure, and therefore control, the concentration on a material in a solution through the use of refraction.

Refractive Index

The refractive index (RI), is the ratio between the speed of light in vacuum and the speed of light in a given media. It determines how much light is bent, or refracted, when entering a material. The Refractive Index of air is 1.0003, and the RI of most gases, liquids, and solids is between 1 and 2.

Refractive Index is defined as:

- RI= Speed of Light in Vacuum / Speed of Light in a Particular Medium

Applying Refraction to Food and Beverage Processing

Food and beverage industries prefer to use their own units rather than the index of refraction for controlling quality of their product. Examples are measuring sugar content in tomato products, citrus juices, and jams and jellies. These industries prefer to use the % Brix scale, which refers to the sugar concentration. Refractive Index is easily converted to % Brix units through simple calculations.

Inline Refractometers for Large Scale Food and Beverage Production

Inline Refractometers for Large Scale Food and Beverage Production

Industrial inline refractometers directly measure the Refractive Index of process fluids and then

display the reading in any number of customer-desired units such as Brix,

Percent Solids, Dissolved Solids, etc.

|

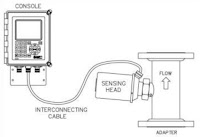

| Inline refractometer in food and beverage process highlighting sensing element and electronics console. |

There are two primary components to an inline refractometer, the electronics console and the sensing head.

The electronics console usually contains a display of some type, and provides a standard output such as 4-20mA. Optionally, there may be some form of networking protocol such as HART® or RS-232/422.

The sensing head is installed in line by mounting the prism assembly in a pipe and inserting this pipe section in the process line. Vessel mounting is accommodated by having the prism assembly inserted in a flange that can be attached to a storage tank or mixing tank.

For more information on any commercial or industrial application for inline refractometers, contact visit Electron Machine at http://www.electronmachine.com or call 352-669-3101.