This blog focuses on industrial, inline process refractometers and their use in industrial applications. Refractometry is used to measure the refractive index of a substance in order to determine its composition or purity. Posts include information on theory, construction, installation, new products and new markets.

Electron Machine Corporation | Umatilla, FL | PHONE: 352-669-3101 | ElectronMachine.com

Sweet Precision: How Inline Process Refractometers Transform Large Scale Ice Cream Production

https://electronmachine.com

+1 352-669-3101

Shedding Light on Quality: The Role of Process Refractometers in Tomato Processing

What is a Process Refractometer?

Importance in Tomato Products

- Brix Measurement: Brix is a scale that indicates the sugar content of an aqueous solution. One degree Brix corresponds to 1 gram of sucrose in 100 grams of solution. In the tomato industry, the Brix measurement helps determine the sugar concentration in tomato products like sauces, ketchup, and pastes. A consistent Brix level ensures a uniform taste across batches.

- Ensuring Quality: Besides flavor, the concentration of soluble solids in tomato products affects texture and viscosity. By constantly monitoring this concentration, manufacturers can make real-time adjustments to the processing parameters, ensuring the end product maintains the desired quality.

- Economic Considerations: Overconcentration means more tomato content than necessary, which can waste resources, while underconcentration might not meet industry standards or consumer expectations. By maintaining the right concentration, manufacturers can optimize costs.

- Safety Concerns: Water activity in a product can influence its susceptibility to microbial growth. By monitoring and controlling the concentration of solutes, manufacturers can enhance tomato products' safety and shelf life.

Practical Applications

- Tomato Paste Production: Refractometers ensure that the concentration process yields a consistent product for direct consumption or as a base for other tomato-based products.

- Ketchup & Sauces: Beyond tomatoes, these products often contain additional ingredients like spices, sugars, and vinegar. Monitoring the overall concentration ensures a balanced product that meets the desired flavor profile and texture.

- Canned Tomatoes: While these are processed less than paste or ketchup, providing the brine or juice's concentration can affect the product's overall taste and shelf life.

- Juice Production: Whether it's pure tomato juice or a blend, maintaining the right Brix level is essential for consistent flavor and quality.

https://electronmachine.com

+1 352-669-3101

Electron Machine Corporation: Pioneering Industrial Refractometers

https://electronmachine.com

+1 352-669-3101

Process Refractometers in The Kraft Pulping Process

- Green Liquor Control: After burning the black liquor, the resulting green liquor contains sodium carbonate (Na2CO3) and sodium sulfide (Na2S). Refractometers measure the green liquor's concentration, which helps optimize the causticizing process. This process involves converting sodium carbonate to sodium hydroxide by adding lime (calcium oxide, CaO). Accurate measurement of green liquor concentration ensures the right amount of lime is added, thus optimizing the efficiency of the causticizing process and reducing waste.

- Brown Liquor Control: After the causticizing process, the remaining liquor, called "brown liquor," primarily contains sodium hydroxide (NaOH) and sodium sulfide (Na2S). The concentration of brown liquor is critical for achieving the desired pulp quality and yield. Refractometers help maintain the correct concentration of brown liquor, ensuring consistent pulp quality and minimizing chemical waste.

- Black Liquor Evaporation: Black liquor is concentrated through evaporation to increase its solids content before being burned in the recovery boiler. Process refractometers monitor the concentration of the black liquor, ensuring optimal evaporation rates and preventing potential issues in the recovery boiler.

- White Liquor Quality Control: Refractometers can also be used to monitor the concentration of white liquor, helping maintain the desired alkalinity and sulfide levels, directly affecting the cooking process and pulp quality.

- Recirculation and Monitoring: Process refractometers can be installed at various points in the Kraft pulping process, such as in recirculation lines, to monitor liquor concentrations continuously and adjust process parameters accordingly.

The Evolving Role of Industrial Inline Refractometers: Emerging Applications

Industrial inline process refractometers are devices that measure the refractive index of a medium, which is usually related to its composition or purity. Refractometers measure the degree of change in direction or refraction of light as it passes through a liquid. The refractive index of a liquid can indicate its composition, purity, concentration, and other chemical or physical properties. These devices are widely used in industries such as food & beverage, oil & gas, chemical, pharmaceutical, and paper & pulp.

With the advancement of technology, several promising new applications have emerged:

Waste Water Treatment: Refractometers can be used in wastewater treatment facilities to measure and control the concentration of dissolved solids and other chemicals, helping to optimize the treatment process and ensuring the water is safe for disposal or re-use.

Battery Manufacturing: In producing batteries, refractometers monitor the concentration of electrolytes, helping to ensure the quality and performance of the final product.

Biotechnology: In the biotech sector, refractometers are used in fermentation processes to control sugar and alcohol concentrations in real-time, allowing for better control and optimization.

Renewable Energy: In producing biofuels, refractometers can help monitor and control the concentration of various inputs and products, improving efficiency and product quality.

Precision Agriculture: Using refractometers in precision agriculture can help determine the nutrient concentration in irrigation water and soils, aiding in precision fertilization and irrigation strategies.

Advanced Material Manufacturing: In semiconductor manufacturing or nanotechnology industries, refractometers can accurately measure the refractive index of materials, which is crucial for quality control and process optimization.

Medicine and Healthcare: Though not an industrial application, refractometers can be used in clinical labs to measure the concentration of proteins and other substances in bodily fluids, contributing to better diagnostic and treatment strategies.

Carbon Capture and Storage: In carbon sequestration processes, refractometers can help measure the concentration of CO2 in various mediums, ensuring the efficiency of the capture and storage process.

Food Processing: Beyond traditional use in sugar concentration measurement, new applications in food processing include measuring the concentration of ingredients in complex mixtures, optimizing fermentation processes, and ensuring the quality of finished products.

Cosmetics and Personal Care Products: Refractometers can help ensure the quality and consistency of products such as soaps, creams, and shampoos by measuring the concentration of various ingredients.

As technology advances, the potential for new applications continues to grow. Continued accuracy, automation, and data integration improvements will drive further use of refractometers across various industries.

One of Electron Machine's distinctive offerings is its MPR E-Scan, an inline process refractometer that provides continuous, real-time measurement. What's fascinating about the MPR E-Scan is its ability to stand up to harsh industrial environments. It's built with a rugged, stainless-steel body and sapphire prism, ensuring it remains unaffected by abrasive or corrosive substances. The MPR-E-Scan also operates under extreme temperature and pressure conditions. Furthermore, their refractometers include modern communication capabilities, which means they can seamlessly integrate with process control systems, helping to optimize efficiency and quality control within a production line.

Electron Machine Corporation

https://electronmachine.com

+1 352-669-3101

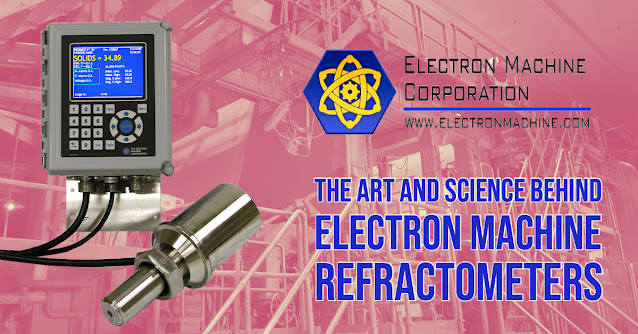

The Art and Science Behind Electron Machine Corporation's Refractometers

Electron Machine Corporation is known for high-quality industrial-grade process refractometers. Here's a general explanation of the principles, technologies, and construction behind their refractometers.

Principle of Refractometry:

A refractometer operates on the principle of refraction. When light passes from one medium to another, it changes direction, called refraction. A refractometer measures the degree to which the light changes direction, i.e., the angle of refraction.

A process refractometer uses this principle to measure a process fluid's refractive index (RI). The refractive index measures how much the speed of light reduces within the fluid. It's a characteristic property of each substance and is influenced by temperature and concentration. For solutions, the refractive index can be used to determine the concentration of solutes in the solution, and this is how process refractometers find application in industries.

Technology Behind Electron Machine Corp. Refractometers:

Here's an overview of how these refractometers may function:

- Light Source: A light source emits light into the prism assembly. This light source is usually a long-life LED.

- Prism Assembly: This is where the process fluid comes in contact with the refractometer. The prism assembly usually contains a high-refractive-index glass prism that comes into contact with the process fluid. The light from the source enters the prism and is refracted (or bent) when it exits the prism into the process fluid.

- Detector: After the process fluid refracts the light, it hits a linear photodiode array, the detector. Depending on the refractive index of the process fluid, the angle of the light will change, causing the light to hit the detector at different positions.

- Signal Processing: The refractometer's electronics convert this positional information into a digital signal converted to a refractive index measurement. The device uses the known refractive index of the prism and the angle of refraction to calculate the refractive index of the process fluid.

- Temperature Compensation: Since the refractive index is temperature-dependent, high-quality refractometers will also include a temperature sensor to measure the process fluid's temperature. The device will then apply temperature compensation to correct the refractive index measurement.

- Output: The refractive index or the converted measurement related to the process (like Brix in the food and beverage industry, concentration in the chemical industry, etc.) can be communicated to a central system using standard industrial communication protocols.

Rugged Design and Construction of Electron Machine Refractometers

The refractometers manufactured by Electron Machine Corporation are rugged. They are designed for industrial use in harsh conditions with high temperatures, significant vibrations, and heavily contaminated settings. The refractometer withstands extreme conditions that damage conventional equipment, including considerable temperature fluctuations, high vibration levels, humidity, dust, and potential physical shocks or impacts. They have robust electronics and casings and are built to resist wear and tear, thereby ensuring reliable operation in challenging environments.

https://electronmachine.com

+1 352-669-3101

Optimizing Quality and Efficiency in Tomato-Based Products with Inline Process Refractometers

Introduction

The food processing industry constantly seeks innovative ways to enhance quality control, improve efficiency, and reduce waste. One such innovation that has significantly impacted is the inline process refractometer. This instrument is beneficial in producing tomato-based products, where consistent quality is paramount. This article explores the importance of refractometers in tomato processing, highlighting their benefits and applications in the industry.

Understanding Inline Process Refractometers

An inline process refractometer measures the refractive index of a liquid, which is directly related to its concentration. In the food processing industry, this measurement can provide crucial information about the concentration of ingredients such as sugar, acids, and soluble solids. Inline refractometers integrate directly into the processing line, allowing for real-time, continuous product monitoring.

Applications in Tomato-Based Products

Tomato-based products, including ketchup, tomato sauce, paste, and juice, require precise control over their concentration and consistency to ensure product quality, taste, and shelf life. Inline process refractometers are crucial in achieving these goals, providing real-time data on critical parameters. Some key applications include:

- Brix measurement: Brix measures soluble solids, primarily sugars, in a liquid. Brix is an essential quality parameter in tomato-based products, impacting taste and consistency. Inline refractometers help maintain the desired Brix level by continuously monitoring the concentration of soluble solids throughout the production process.

- pH monitoring: The pH level of tomato-based products is critical to their taste, texture, and preservation. Inline refractometers can be used with pH meters to ensure the product's acidity remains within the desired range.

- Concentration control: The concentration management of tomato-based products must maintain product quality and reduce waste. Inline refractometers enable manufacturers to monitor and control the concentration of tomato solids, ensuring that the final product meets customer expectations.

- Evaporation and dehydration: Reducing tomato-based products' water content is essential for taste and preservation. Inline refractometers provide real-time data on product concentration, allowing manufacturers to optimize the evaporation and dehydration processes to achieve the final product.

Benefits of Inline Process Refractometers in Tomato Processing

The use of inline process refractometers in the food processing industry, particularly in tomato-based products, offers numerous advantages:

- Enhanced quality control: Continuous monitoring of critical parameters such as Brix, pH, and concentration ensures consistent product quality and compliance with industry standards.

- Reduced waste: Real-time data on product concentration enables manufacturers to adjust quickly, reducing waste and minimizing losses.

- Improved efficiency: Inline refractometers streamline the production process by eliminating the need for manual sampling and testing. This results in reduced downtime and increased throughput.

- Cost savings: Inline refractometers can significantly reduce production costs in the long run by optimizing processes and minimizing waste.

Conclusion

Inline process refractometers have become indispensable in the food processing industry, particularly in tomato-based products. These instruments help manufacturers maintain high-quality standards while optimizing efficiency and reducing waste by providing real-time, continuous data on critical quality parameters. As the industry continues to evolve and innovate, adopting inline process refractometers is expected to grow, further enhancing the quality and consistency of the tomato-based products we know and love.

The Crucial Role of Inline Process Refractometers in Manufacturing Industries

Industrial refractometers are an indispensable component of process automation because they contribute to maintaining product quality and uniformity, reducing waste, and enhancing output. A substance's refractive index can be determined using a refractometer, which assesses the degree to which a sample causes light to bend as it travels through the process media. This measurement provides helpful information regarding the composition and concentration of a solution, both of which are essential in a wide variety of industrial processes.

Industries That Commonly Use Inline Process Refractometers:

- Inline process refractometers are used in pulp and paper manufacturing to determine the percent of dissolved solids present during various stages of the production process. These phases include the pulping process, the bleaching process, and the paper coating process.

- Inline process refractometers are commonly used in the food and beverage sector to determine the percentage of sugar occurring in various goods like juices, jams, and other condiments. This measurement contributes to ensuring that the products have a consistent flavor and texture across the line and meet all regulatory criteria.

- In the pharmaceutical sector, process refractometers measure the concentration of active pharmaceutical substances, an essential step in ensuring the product is effective and safe.

- In the production of semiconductors, inline process refractometers measure the concentration of chemical solutions utilized in various production processes. These processes include cleaning, etching, and chemical mechanical planarization.

- Process refractometers assist in producing industrial chemicals to measure the concentration of dissolved solids such as salts, acids, and other compounds at various points throughout the production process.

Industrial refractometers offer real-time, precise, and dependable measurements by automating the process of measuring refractive index, thus eliminating the need for manual testing. This automation minimizes errors, enhances process efficiency, and reduces labor costs that result from manual testing. Additionally, automated refractometers supply data to distributed control systems and PLCs, enabling continuous monitoring and regulation of essential process parameters.

In general, industrial refractometers play an essential part in the automation of processes. They contribute to the maintenance of product quality and consistency, as well as to the enhancement of efficiency and productivity, as well as to the reduction of waste and expenses. As automation technology progresses, refractometers and other process monitoring devices may take on an even more significant role in industrial settings.

Electron Machine Corporation

https://electronmachine.com

+1 352-669-3101

Process Refractometers for Brewing Beer

Qualitative Analysis of Black Liquor in the Kraft Process

Black liquor is a byproduct of the Kraft process of paper production. The Kraft process, also known as the sulfate process, is a method of pulping wood chips to produce wood pulp, which is then used to make paper. In the Kraft process, wood chips are cooked in a solution of sodium hydroxide (NaOH) and sodium sulfide (Na2S) at high temperatures and pressure. This chemical cooking process breaks down the lignin and cellulose in the wood chips, separating the fibers that can be used to make paper.

During the cooking process, a black, viscous liquid known as black liquor is produced. Black liquor contains lignin, hemicellulose, and other organic compounds that are dissolved or suspended in the cooking liquor. It also contains inorganic chemicals such as sodium hydroxide and sodium sulfide, as well as dissolved minerals from the wood chips.

Black liquor is separated from the wood pulp during the pulp washing and recovery process. It is then burned in a recovery boiler to generate steam and electricity for the mill. The heat from the burning black liquor drives a steam turbine, which generates electricity that can be used to power the mill and any excess can be sold back to the grid. The inorganic chemicals in the black liquor are also recovered and recycled back into the Kraft process.

Process refractometers are used in paper mills to analyze black liquor in order to determine its concentration and solids content. The concentration of black liquor can have a significant impact on the efficiency of the pulping process, so it is important to accurately measure it.

To use a process refractometer to analyze black liquor, a sample of the liquor is typically collected and placed in a sample cell. The refractometer then measures the refractive index of the sample, which is a measure of the way that light is bent as it passes through the sample. The refractive index of the sample is then used to calculate the concentration of the black liquor.

Process refractometers are widely used in paper mills because they are fast, accurate, and easy to use. They can also be used to measure the concentration of other process fluids, such as process water and spent cooking liquor.

For more information on the use of inline process refractometers for black liquor analysis, contact Electron Machine at +1 352-669-3101 or visit http://electronmachine.com.