The beverage sector creates widely consumed goods while adhering to stringent quality standards. Producers of beverages are responsible for ensuring adequate quality and meet rising customer demands for innovative and consistent flavor. Reliable process control tools are required to make production viable and sustainable and maintain the highest levels of product quality. In this age of sophisticated technologies, it's essential for best practice manufacturing standards.

The degree of Brix (°Bx) indicates the amount of sugar in an aqueous solution. One degree Brix equals one gram of sucrose in 100 grams of solution and suggests the solution's strength as a percentage of mass. Brix monitoring and measurement are critical for various beverages, whether dairy, brewery, wine, soft drinks, or fruit juices.

In the beverage and juice industry, syrups and concentrates are blended with water, or fermented, according to specific recipes, stored in stacking tanks, and finally filled into product-specific bottles or containers. A standard method for Brix testing is a manual process done in a remote lab with samples taken from the process. If a primary component, such as a juice concentrate, does not precisely meet the specifications, or if the blending process itself is incorrect due to incorrect flow control, the entire production run may be flawed. Cross-contamination is another concern. If a wrong product is mixed and bottled due to a poorly controlled phase transition, rejection of the whole batch is the outcome.

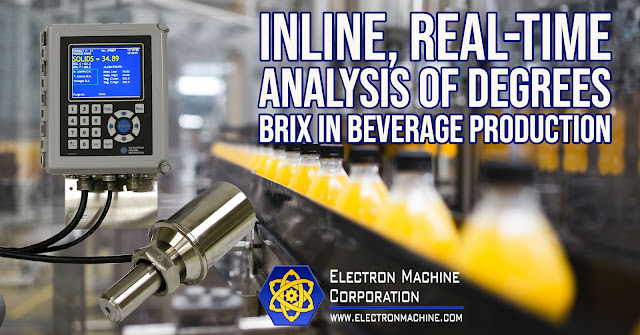

The inline refractometer (a robust process control instrument) provides a highly reliable and precise measure of Brix in beverage production. Inline process refractometers are installed in the process piping and continuously measure the Brix value, constantly measuring the definition and differentiation of each product, component, juice, or beverage.

The advantages are clear for choosing inline refractometers. The time-consuming and labor-intensive manual sampling and laboratory analysis are less efficient and less repeatable. The more efficient and reliable solution is the inline process refractometer. These devices offer real-time, inline continuous concentration measurement and cross-contamination protection. Additionally, operators can use their time to perform other critical activities, enabling other time-savings quality improvements.

Electron Machine Corporation

https://electronmachine.com

+1 352-669-3101