Hydrochloric Acid, HCL, is a versatile chemical used in a number of industrial chemical processes such as hydrometallurgical processing, chlorine dioxide synthesis, hydrogen production, and petroleum well activation. Hydrochloric Acid is also commonly used in various metal etching and cleaning processes (pickling of steel), masonry cleaning processes, and the production of plastics (such as PVC), polyurethane production, leather tanning, and in food additive processing. The dilute version of HCL is Muriatic Acid, which was originally called "acidum salis" and "spirits of salt" because it was produced from rock salt in the 15th century.

Measuring the Concentration of Hydrochloric Acid (sometimes referred to as Concentration Density of Hydrochloric Acid) is a critical part of the production process for all applications mentioned above. It is important to closely monitor the concentration levels of the hydrochloric acid with a high degree of accuracy and reliability. Although Hydrochloric Acid Concentration can be created in excess of 40% (Concentrated Grade), Industrial Grade high concentration HCL is 30-35%, which is most stable for transport and storage, and reduces the loss of HCL to evaporation. As the concentration lowers, other names for the concentrations exist, such as Muriatic Acid which can range in concentrations of 21-35%.

Hydrochloric Acid is a prime candidate for concentration measurement through use of its Refractive Index (R.I.). Unlike Sulfuric Acid, the R.I. for HCL Acid is extremely linear, rising from 0% at 1.333 R.I. to 40% at 1.425 R.I.

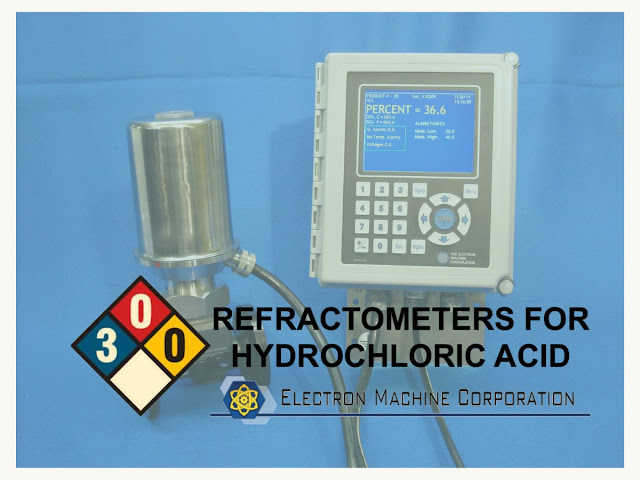

An inline process refractometer is used to monitor the concentration of Hydrochloric Acid level in real time. Based upon the refractive index (R.I.) of a given aqueous solution, the refractometer can determine the HCL concentration of the solution and relay that value in real time for proactive process control.

The Electron Machine Corporation’s family of inline process refractometers are the ideal instrument for measuring these concentrations.

Electron Machine Corporation manufactures the MPR E-Scan; a rugged, dependable, accurate, and cost effective in-line refractometer. Capabilities include 4-20mA and 0-10VDC outputs, a variety of up to 8 internal relays for direct control of a variety of valves, alarms, and warning indicators, as well as the capability of saving up to 99 different recipes each with their own alarms, set-points and controls. The wetted metal of the sensing head is normally made from Tantalum (other alloys are available). The non-wetted parts and the interconnection cable can be Teflon® coated for added protection.

Benefits of Using the MPR E-Scan:

- High precision and durability in extremely corrosive conditions.

- Continuous quality control.

- Hazardous chemical environmental and safety regulation compliance.

- Low maintenance, repeatable operation.

Please contact Electron Machine Corporation (+1 352-669-3101) for more information or check out our many accounts on social media.